Quality commercial ovens since 1977

Hounö blog

Future-proofing your kitchen: Why Invoq and Desmon are the perfect Cook & Chill pairing

Boost up the central kitchen production with the Invoq Combi oven & Desmon blast chiller, ensuring food safety while saving resources.

For institutional kitchens, catering companies, and large-scale foodservice operations, delivering consistent quality while ensuring food safety is more than just best practice – it’s a necessity. That’s where Middleby’s cook & chill powerhouse comes in: the Invoq Combi oven and the Desmon blast chiller. These two professional kitchen appliances work hand-in-hand to streamline your workflow, extend shelf life, and elevate food safety without compromising on taste, texture, or nutrition.

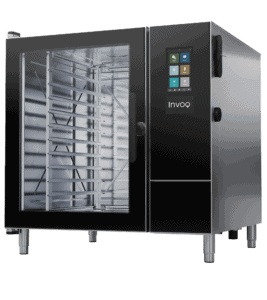

Smarter cooking with Invoq Combi oven

The Invoq Combi oven is engineered for performance and precision. Whether you are steaming, roasting, baking, or regenerating, Invoq’s intelligent features adapt to your kitchen’s needs – day in, day out.

Invoq helps institutional and catering kitchens:

- Cook large volumes efficiently while maintaining uniform results.

- Reduce energy, water, and detergent usage with eco-friendly cleaning cycles.

- Keep staff safe and productive with a user-friendly interface and smart automation.

- Ensure HACCP-compliant cooking with built-in traceability features.

From schools to hospitals and contract catering operations, the Invoq oven is the reliable foundation for any professional kitchen’s hot prep process.

Rapid cooling

Desmon Blast Chiller

Whether it is portioned meals for a canteen, pre-cooked sauces for a central kitchen, or desserts for an event, Desmon gives operators the confidence to prepare in bulk without loss in quality.

• Blast chill from +90°C to +3°C in 90 minutes to comply with HACCP requirements.

• Shock freeze from +90°C to -18°C in 240 minutes, locking in freshness for up to 12 months.

• Retain the food’s original aroma, structure, color, and nutritional value.

• Improve kitchen organization with pre-prep flexibility and better portion control.

• Minimize food waste and reduce cost per serving.

Visit Desmon official website to learn more

Regeneration made simple

Once food has been cooked in the Invoq Combi oven and blast-chilled or shock-frozen in the Desmon unit, it can be safely stored for future service. When the time comes, meals can be brought back to optimal serving temperature through a precise regeneration process – without compromising texture, flavor, or nutritional value.

Thanks to its advanced steam and convection capabilities, the Invoq Combi oven handles regeneration with exceptional accuracy, making it ideal for decentralized or satellite kitchens.

Why the Cook & Chill process works

When used together, the Invoq oven and Desmon blast chiller create a highly efficient cook & chill cycle. Food is cooked to perfection in Invoq, rapidly chilled or frozen in Desmon, and safely stored for later regeneration – ensuring food safety, flexibility, and unbeatable consistency.

Benefits of combining Invoq + Desmon

- Seamless workflow from cooking to storage.

- Better time and labor planning – prepare meals ahead and regenerate on demand.

- Reduce food waste with extended shelf life and precise portioning.

- Maintain high food quality across multiple days of service or delivery.

- Boost profitability with lower production costs and reduced energy waste.

Built-in traceability and smart data integration

Both Invoq and Desmon are equipped to support full data integration within modern kitchen management systems. With built-in HACCP compliance features, they log and store critical time-temperature data automatically. This allows kitchen managers to generate reports, track performance, and ensure full traceability – from the moment food is cooked, to chilling, storage, and final service.

Whether you are running a hospital kitchen or a multi-site catering operation, these data-rich systems help streamline workflows and ensure food safety with confidence.

The essence of large-scale foodservice operation

Designed with sustainability in mind

Energy savings and environmental responsibility are baked into the design of both the Invoq oven and Desmon blast chiller. Invoq features eco-friendly CareCycle cleaning programs that reduce water consumption by up to 27% and cleaning time by up to 63% compared to earlier models.

Desmon takes it further with Cyclopentane insulation – an environmentally responsible solution with zero ozone-depleting potential. Combined with indirect airflow systems, intelligent defrost cycles, and energy-efficient cooling modes, Desmon blast chillers are engineered for kitchens aiming to lower their carbon footprint and support green certification goals.

Simplifying training and daily operation

High staff turnover is a reality in many commercial kitchens, which is why ease of use is essential. Both Desmon and Invoq feature intuitive, touchscreen-based interfaces with guided programs and multi-language support. These smart systems reduce training time significantly, lowering the risk of human error while ensuring consistent results across shifts and locations.

Whether onboarding new team members or rolling out new menus across multiple sites, these appliances are built for clarity and speed.

Unlock menu flexibility and operational scalability

The cook & chill process opens the door to greater menu variety with less pressure on daily production. By separating preparation from service, kitchens can offer allergen-specific meals, dietary adaptations, and seasonal dishes without overloading the team during peak hours.

With the ability to cook, chill, and regenerate on demand, Invoq and Desmon allow foodservice providers to scale up batch cooking while maintaining culinary excellence and nutritional integrity.

Real-world use scenarios

- Hospital kitchens: Meals can be cooked in advance and regenerated ward-side, ensuring safe and hygienic service with consistent nutritional profiles.

- Airline catering: Hundreds of meals can be shock-frozen with Desmon, preserving quality for long-haul storage and high-altitude service.

- School canteens: Large volumes of meals are prepped, chilled, and portioned ahead of time, then regenerated for service with minimal waste and labor.

- Event catering: Dishes are prepared centrally, blast-chilled, and then transported for seamless regeneration at the venue.

Built for high-performance environments

Both appliances are designed to withstand the demands of high-volume, professional kitchens. The Invoq oven and Desmon blast chiller are fully compatible with 1/1 GN and 600 x 400 EN trays, making it easy to transfer food between cooking and chilling without the need to replate or repack. This not only ensures a smooth and hygienic cook & chill process but also saves valuable time and reduces handling errors.

Desmon’s stainless steel AISI 304 interiors, intelligent airflow systems, and rapid temperature transitions make it ideal for institutional and catering use. Likewise, Invoq’s robust construction, high-speed airflow, and multi-mode cooking capabilities ensure reliable, high-quality results – batch after batch.

From institutional kitchens needing daily repetition to catering services operating across time and location, the Invoq and Desmon combination is a reliable, scalable investment in operational excellence.

Transform your kitchen with Middleby’s best

Guides and Inspirations

Revolutionize central production kitchen with Invoq Combi oven and Firex Figaro